NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

Long-term railway planning make aggregate demand continues strong

By 2025, China will build 54,000 km of railway which will drive 11-16 million tons of aggregate demand.However, natural sand resources are limited. The traditional mechanism sand has uneven grading and too much impurity which can not meet the quality requirements for aggregate in the high-speed railways, highways and other projects.

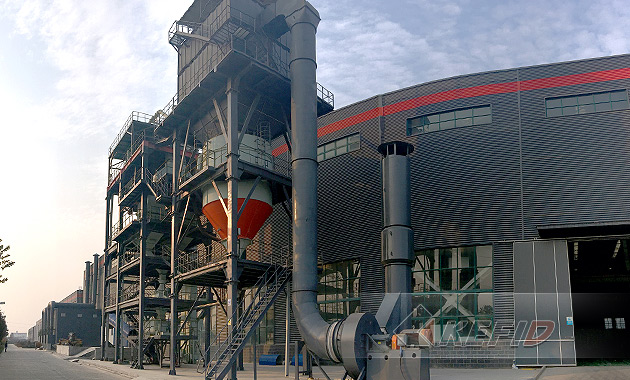

In view of this situation, Kefid VU aggregate optimization system carry out comprehensive upgrade based on the original dry sand making system.It use highly intensive tower-type closed, set efficient sand making, grain optimization, stone powder control, grading adjustment, moisture control, environmental treatment in one, so that the performance of sand is comparable to natural sand.

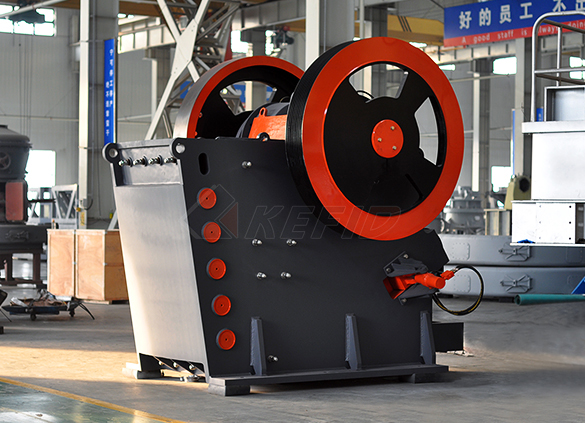

In order to reduce the needles and burr-shaped sand, VU aggregate optimization system adopt VU vertical shaft impact crusher and VU grain optimization machine. VU vertical shaft impact crusher can effectively eliminate the needle sheet material which substantial improve grain shape of finished sand; VU grain optimization machine can effectively remove the burrs and residual edges and corners on the surface of the finished sand and can increase -0.6mm fine material, porosity decreased 1%-2%, flow time decreased by 5%.

At present, Kefid VU aggregate system has been applied to many gravel production projects in the world and supplied a large number of high-quality aggregate for railways, highways, hydropower projects.