NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

The process of aluminum ore beneficiation production line

Aluminum ore belongs to metal ore, it has high hardness. Its processing is different with other non-metallic minerals.

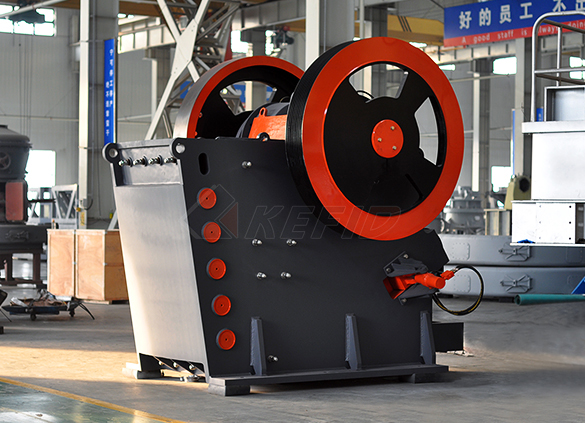

Kefid is Asia's high-end production and export base of crushing and grinding equipment, we produce jaw crusher, cone crusher (hydraulic and spring), impact crusher, sand making machine, ball mill, vertical mill, raymond mill,etc. According to aluminum ore characteristics and application requirements,we designed full set of aluminum ore solutions for global customers.

Aluminum ore processing technology include three stages: crushing, grinding, beneficiation.

The first stage: crushing and screening

Chunks of aluminum ore are sent by vibrating feeder to jaw crusher or mobile jaw crusher for coarse crushing; then after sieving by vibrating screen,the crushed stone are transffered by belt conveyor to single-cylinder hydraulic cone crusher for secondary crushing; finally into multi-cylinder hydraulic cone crusher for fine crushing.We can adjust the fineness to reach 13mm or less.

The second stage: milling

The crushed aluminum ore are sent into ball mill for grinding and screening by spiral classifier. The products which does not meet the requirements will be fed into the ball mill for re-grinding.

The third stage: beneficiation

The aluminum powder which meet the requirements are send into flotation machines for flotation and then fed into the dryer to obtain final powder.