MTW EUROPEAN TECH. GRINDING MILL

COMPETITIVE BRANDS OF THE SAME CLASS

In recent years, China's grinding mill market is very prosperous and competitive. What kind of grinding mill exactly is most suitable for Chinese customers?

Recently, an ultimate showdown between MTW European Tech. Grinding Mill and another hot sale brand is unfolding, and we will evaluate the grinding mill of the same model in capacity, production efficiency and innovative technology, and announce the performance results.

Chief engineer of KEFID grinding mills, Mr. Bai Yinghui said, "In China, many customers only consider the capacity when choosing the grinding mill, but ignore the production efficiency. Today we will duke it out at site."

CAPACITY PK

PRODUCTION EFFICIENCY PK

INNOVATIVE TECHNOLOGY PK

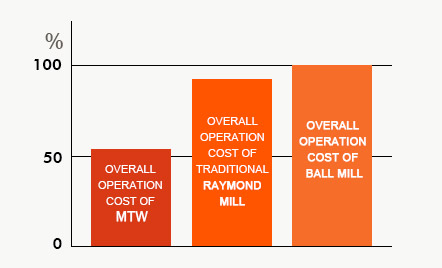

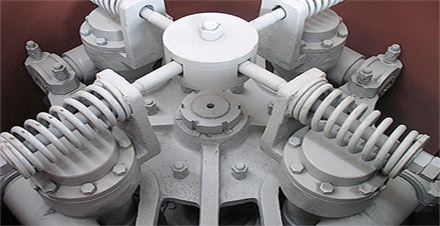

MTWM European Tech. Grinding Mill keeps many advantages of TGM grinding mill especially the linkage pressure of the rollers, which greatly prolongs the useful life of the equipment and increases the capacity by 20% under the same power.

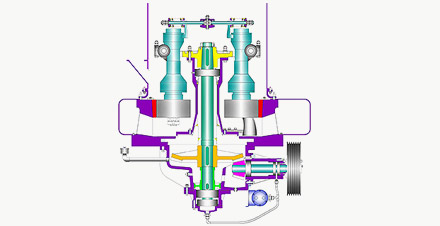

The MTW is driven through the bevel gear and compact in its structure, thus it is quite easy to be installed and adjusted; While the traditional mill has to be equipped with a reducer which drives the main axis through coupling, it is rather difficult to be centered while being installed, and it's noise-making and inefficient.

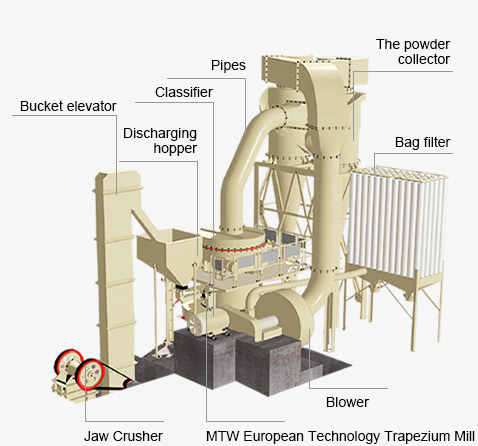

First, raw material should be crushed by the jaw crusher to the size specified, and then the crushed stuff is elevated into a hopper from which the stuff is loaded, through the vibrating feeder, evenly and continuously into the grinding chamber for powder-processing.

After this, the ground stuff is carried by the air into the separator for screening. The fine powder are blow into the cyclone collector and are poured out through the output-powder valve as the final products and the rough stuff after the screening will be recycled back into the grinding chamber for regrinding.

The set's airflow system is closely sealed up and circulated under condition of negative pressure.

PRODUCTION SITE

MTW European Tech. Grinding Mill can be widely used for grinding the following non-flammable and non-explosive materials with Moh's hardness and moisture lower than 9.3 and 6% respectively, such as quartz, feldspar, calcite, talc, barite, fluorite, marble, ceramics, bauxite, mineral slag, grain slag, cement clinker, activated carbon, dolomite, granite, , fertilizer, kaolin, coke, bentonite, pyrophyllite, basalt, gypsum, graphite, etc. Next, let's see production sites of MTW European Tech. Grinding Mill from all over the world.

Material: limestone Feeding size: 0-5mm Final size: 0.1-0.6mm Capacity: 40t/h

Configuration: Speed governing constant belt weigher + electro-vibrating feeder(GZ5F)+MTW215 European grinding mill (with coarse powder tube) +Pulse bag filter .

Client situation: This is the second time for this client to cooperate with KEFID. The most important factor they choose us is MTW215, which is the biggest model of pendulum mill in the world. KEFID is the original manufacturer in China to supply this kind of High Capacity Limestone Grinding Mill, we had cooperated with this customer for fours years. The other two important factors he chose us is KEFID's professional technology and perfect after-sale service: "Our site space is limited in Thailand , but KEFID chief engineer gave us a special design for the grinding mill according to my site situation. I like their service and I trust KEFID. "

Material: limestone Feeding size: <40mm Final size: 0.08mm Capacity: 6t/h

Configuration: stock bin + vibrating feeder +MTW110 European grinding mill

Client situation: This client originally used our old Overpressure Trapezium Mill, and was very satisfied with our product quality and after-sales service. With the upgrade of our products, the client unhesitatingly chose our latest MTW European Tech. Grinding Mill to enlarge their production line. The equipment adopts advanced inner thin-oil lubricating system with easy repair and maintenance, moreover, replaceable shovel blade in hook face prolongs the service time of wearing parts, all these can greatly reduce the replacement cost in later period. So far the equipment operates in stability and local customers take delight in talking about it.

Material: limestone Feeding size: 15mm Final size: 0-0.7mm Capacity: 17t/h

Configuration: Bucket elevator (TH315x10.2m)+ adjusting stock bin +electro-vibrating feeder(GZ3F)+MTW175 European grinding mill.

Client situation: This client didn't believe in our finished product ratio at first. After 3 times actual field experiments, finally the client was deeply convinced that our equipment can meet their requirements. The client had considered other manufacturers before us, but after visiting our site, he was deeply impressed by our site's clean surroundings and advanced lubrication system, which greatly reduced the customers' operation cost and met the high demand of European environmental protection, therefore, the client happily decided to cooperate with KEFID.

RELATED PRODUCTS