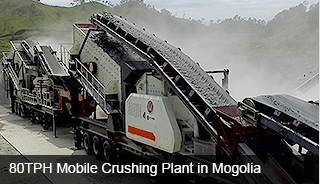

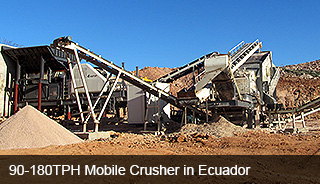

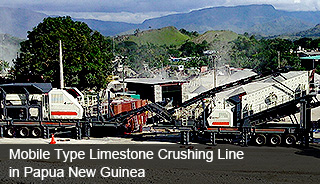

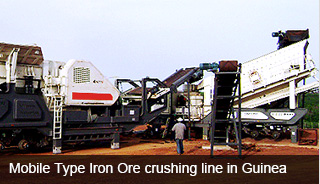

K series mobile crushing plants are aimed at satisfying customers' diversified demand for high quality and high yield, thus to create maximized value for

customers. 7 modules and 72 types with tremendous momentum make the plant a generalist in crushing field, because it can be used in almost all the fields

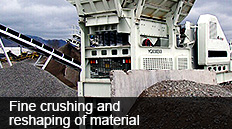

such as coarse crushing, medium crushing, fine crushing, super fine crushing and screening, etc.