NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

Kefid can provide a complete of processing equipments for processing copper ore in Chile

Recently, the world's largest copper producer - Chile's National Copper Corporation on Wednesday said the country's environmental regulatory authorities have approved the company's $ 5.4 billion worth of sulfide ore project, which is a key part of the company's plans to lift output.

It is understood that the Chile's National Copper Corporation will build a daily processing capacity of supporting 200,000 tons of copper concentrator for new projects in Chile's Atacama desert.

Copper ore is generally an aggregate of sulfide or oxide copper and other minerals. Copper ore processing technology include: crushing, grinding, beneficiation three processes. In crushing process,three-stage closed-circuit crushing are the most suitable for high hardness copper ore crushing to improve the follow-up grinding efficiency; in grinding process, two-stage grinding is efficient grinding process which can make copper more fully grinded; in beneficiation process, the more successful and new technology in recent years is bulk flotation process.

As a global strength mining,crushing production and export base, Kefid focus on copper ore processing equipment for thirty years and we can provide a complete processing technology and new equipment for Chile's copper concentrator project.

The first stage: the crushing and screening - three-stage closed circuit crushing

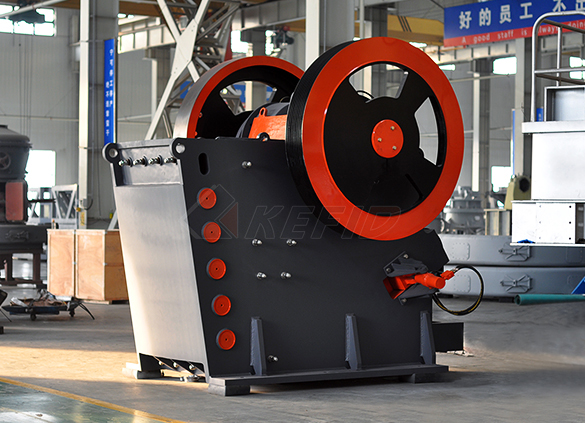

Chunks of copper ore was feed by vibrating feeder to jaw crusher or mobile station for primary crushing; after sieving by vibrating screen, copper ore are transferred by belt conveyor to the single-cylinder hydraulic cone crusher for secondary crushing; after secondary crushing, the materials were sent into multi-cylinder hydraulic cone crusher for fine crushing; we can adjust the fineness of the material to make it reaches 13mm or less.

The second stage: grinding

The crushed copper ore were sent to ball mill for grinding and screening by the spiral classifier.The material does not meet the requirements will be fed into the ball mill for re-grinding;

The third stage: dressing - new flotation process

The copper powder which meet the requirements was fed into the flotation machine for flotation and then fed into the dryer.Finally we obtain refined copper powder.

Kefid's mobile crusher, PEW European type jaw crusher, HST single-sylinder hydraulic cone crusher, HPT multi-cylinder hydraulic cone crusher, ball mill and other equipment have applied to many copper ore processing project, the effect is significant. If you want to know more about copper ore processing equipment,please contact our 24hour online customer service.