Solution

Why does pumping concrete use continuous granular stones? What are the equipment for stone crushing with continuous grain size?

Why is it necessary to give priority to continuous granular stones for pumping concrete? Because the void fraction of a single grain is larger than that of a continuous grain when the maximum particle size of a stone is the same, the large void fraction should be filled with mortar. The surface area of aggregate in a cubic meter of concrete under the same conditions: the amount of cement required is greater than the amount of continuous gravel. And because the use of continuous granule stones is better than the use of single gravel mixed concrete fluidity, conducive to pumping construction. So we're going to use continuous granular pebbles.

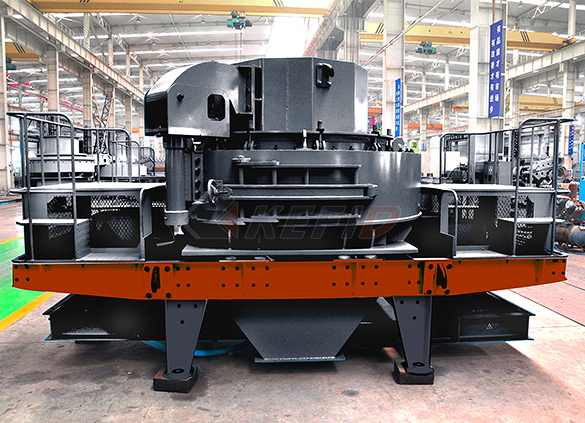

What are the equipment for stone crushing with continuous grain size? Kefid broken family PE jaw crusher, PF impact crusher, HPT cone crusher, VSI6X impact crusher, K series mobile crusher, hard stone can be one-time crushing to the required size, not only reasonable gradation, and the range of output layout ranging from dozens to hundreds of tons, but also with the needs of customers free conversion field is high cost performance of concrete machinery continuous graded gravel crusher.

If you are interested in the concrete machinery equipment of the crushing program, welcome to consult our online customer service or call the hotline, we will wholeheartedly for your service!