TYPICAL STONE CRUSHING PLANT

| 400 TPH Granite Production Line |

| 200 TPH Basalt Mobile Crushing Plant |

| 150 TPH Construction Waste Crushing Plant |

| 100 TPH Dolerite Production Plant |

TYPICAL ORE BENEFICIATION PLANT

| Gold ore beneficiation plant |

| Iron ore beneficiation plant |

| Copper ore beneficiation plant |

| Manganese ore beneficiation plant |

Iron Ore Crushing & Processing

Iron ore is an important raw material for the iron and steel producers. It exists in nature with compounds state, like hematite, magnetite, siderite, limonite,etc. In recent years, with the worldwide development of iron and steel industry, the needs for the iron and processing technologies are increasingly enhanced. KEFID can provide you the crushing and beneficiation for the iron ore, including the machines and technique support.Case: 400 TPH iron ore production line

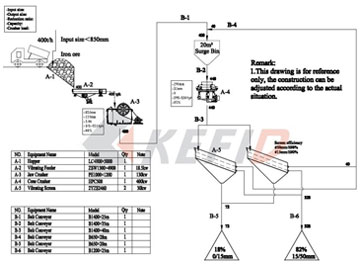

CAPACITY: 400 TPH INPUT SIZE: < 850mm

OUTPUT SIZE: 0-15mm, 15mm-50mm

EQUIPMENTS: 1. Hopper: LC4000*5000 (1 set)

2. Jaw Crusher: PE1000*1200 (1 set)

3. Hydraulic Cone Crusher: HPC500(1 set)

4. Vibrating Feeder: ZSW1300*4900(1 set)

5. Vibrating Screen : 2YZS2460(1 set)

Belts:B1400×25m,B1400×35m,

B1400×40mm,B650×28m,B650×20m, B1200×25m

The description about the plant one

Vibrating feeder ZSW1300*4900 feed the stone into the jaw crusher PE1000*1200 smoothly, which will crush the stone from < 850mm to about 250mm as the primary crusher. Then belt conveyor will take the outputs of PE1000*1200 into the secondary crusher – cone crusher HPC500. Then the outputs of HPC500 will be carried to vibrating screens 2YZS2460, to get separated into 3 kinds materials: 0-15, 15-50, and >50mm. The material is 0-15mm, 15-50mm will be stored as final products. While the material 50mm+ will be carried back to HPC500 for re-crushing.

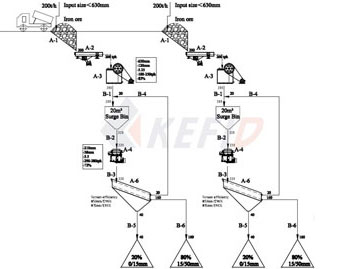

CAPACITY: 400 TPH INPUT SIZE: < 630mm

OUTPUT SIZE: 0-15mm, 15mm-50mm

EQUIPMENTS: 1. Hopper: LC4000*4000 (2 sets)

2. Jaw Crusher: PE750*1060(2 sets)

3. Hydraulic Cone Crusher: HPC300(2 sets)

4. Vibrating Feeder: ZSW1100*4200(2 sets)

5. Vibrating Screen : 2YZS2460(2 sets)

Belts:B1000×25m,B1000×32m, B500×25m, B500×15m, B800×15m

The description about the Plant two

The 400 TPH production line is included by two units of 200TPH production line. Vibrating feeder ZSW1100*4200 feed the stone into the jaw crusher PE750*1060 smoothly, which will crush the stone from <630mm to about 140mm as the primary crusher. Then belt conveyor will take the outputs of PE750*1060 into the secondary crusher – cone crusher HPC300. Then the outputs of HPC300 will be carried to vibrating screens 2YZS2460, to get separated into 3 kinds materials: 0-15, 15-50, and >50mm. The material is 0-15mm, 15-50mm will be stored as final products. While the material 50mm+ will be carried back to HPC500 for re-crushing.The advantages of Plant two:

1、They can work separately. If one of them needs to be checked, the other production line can continue to work. It can't affect your normal production.2、It's convenient for you to control and adjust the capacity you need.