NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

Kefid configurate full set of aggregate production line for the construction of nuclear power plant

Nuclear power plant construction is inseparable from high-grade concrete. The particle size distribution, grain shape, surface features, flakiness particle content of aggregate are key factors affecting the quality of concrete.

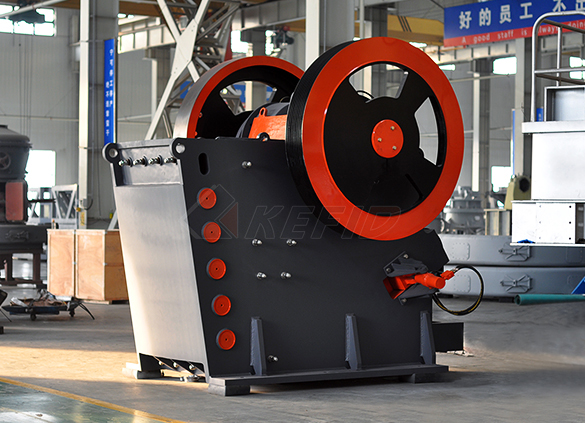

As the high-end crushing and grinding equipment production and export base, Kefid produce K series mobile crusher, PE jaw crusher, HPT/HST hydraulic cone crusher, PF impact crusher, VSI5X sand making machine and other series equipment.We can configure full set of aggregate production line for the construction of nuclear power plant.

For nuclear power plant, we usually use basalt, granite, diabase and other hard rock to produce aggregate. To process this hard rock, HPT hydraulic cone crusher and VSI6S sand making machine are usually standard equipments. They have strong crushing capacity and wear-resistant which can guarantee continuous post-production. If raw material has large size, you can add coarse crusher - jaw crusher.

Production line can adjust a variety of material specifications, such as 1-5mm, 5-16mm, 5-20mm, 16-31.5mm high-quality sand and gravel aggregate. These type of aggregate grain not only has perfect, uniform particle size, and the content of flake stone needles and powder can be controlled in a certain range.

Currently, Kefid has built dozens of aggregate production line for the construction of nuclear power plants in the world and favored by many customers.